Introduction

At MANUCO, we have been helping companies automate their business processes for over ten years, providing modern and efficient technological solutions. One of our key projects in recent years was the implementation of a comprehensive logistics process automation system for BWS Expo – a European leader in the trade fair industry. This initiative not only streamlined their daily operations but also significantly reduced costs and improved work efficiency.

BWS Expo is our long-term client, specializing in the design and construction of trade fair stands across Europe for the world's largest brands. As a leader in the trade fair industry, BWS Expo faces high demands in logistics management and warehouse operations. The company's logistics processes include managing rental products such as furniture and multimedia equipment, as well as overseeing the inventory of materials needed for stand production, including wooden boards, countertops, aluminum structures, and paints. Additionally, BWS Expo handles the planning of shipments to trade fairs, which involves ordering external transport and organizing loading operations at the company’s headquarters.

Challenges

Before the implementation of this project, BWS Expo faced numerous logistical challenges that negatively affected operational efficiency and generated unnecessary costs. The main challenges included:

- Limited control over goods flow – difficulties in tracking the real-time location of individual items throughout the logistics process.

- Issues with material usage accounting – lack of transparency in documentation led to inefficient resource management.

- Time-consuming, manual processing of logistics operations – manual procedures slowed down processes and increased the risk of errors.

- Inefficient transport planning – lack of optimization resulted in excessive use of vehicles and transport resources.

- Frequent loading errors – mistakes during loading required organizing additional deliveries.

- Increased costs due to extra transports – lack of proper control and planning generated unnecessary expenses for additional shipments.

Project Objectives

The primary goal of the collaboration between MANUCO and BWS Expo was to conduct a comprehensive modernization and optimization of logistics processes to meet the company’s growing operational demands. A key element was organizing warehouse management by creating a system that would enable effective and precise inventory control. Introducing transparency and accountability in processes aimed to provide full control over the flow of goods and facilitate easy cost analysis at every stage of logistics operations.

Another important aspect of the project was automating monotonous and repetitive tasks, significantly reducing the manual, time-consuming workload of employees. This allowed the team to focus on more strategic aspects of the company’s operations. The ultimate objective was to eliminate errors that previously led to additional costs and delays. By implementing automated solutions, BWS Expo gained tools to minimize error risks and improve overall operational efficiency.

Project Scope

As part of the project for BWS Expo, we carried out a series of activities encompassing a wide range of technological solutions tailored to the client’s business specifics. The first step was designing and implementing an innovative, dedicated Warehouse Management System (WMS), enabling effective warehouse management and control over all warehouse operations. This system was customized to BWS Expo’s individual needs, considering the trade fair industry’s specifics and the wide variety of managed goods.

The next element of the project was the design and implementation of a module for planning the use of materials at trade fair stands. This module allowed for efficient resource allocation, leading to better management of available materials and minimizing waste. As a result, BWS Expo could better plan material usage at every stage of stand preparation.

We also introduced a module for planning and ordering transports, integrating the management of external carriers and the company’s internal fleet. This optimized transport processes, reduced shipping costs, and ensured timely deliveries.

An integral part of the project was the design and implementation of a loading management module, which improved loading processes at all company sites. Automating this process eliminated loading errors and accelerated logistics operations.

All these modules were integrated into a single automated IT system, ensuring seamless cooperation between the system’s components. This integration facilitated easy processing of warehouse operations and real-time tracking of goods flow.

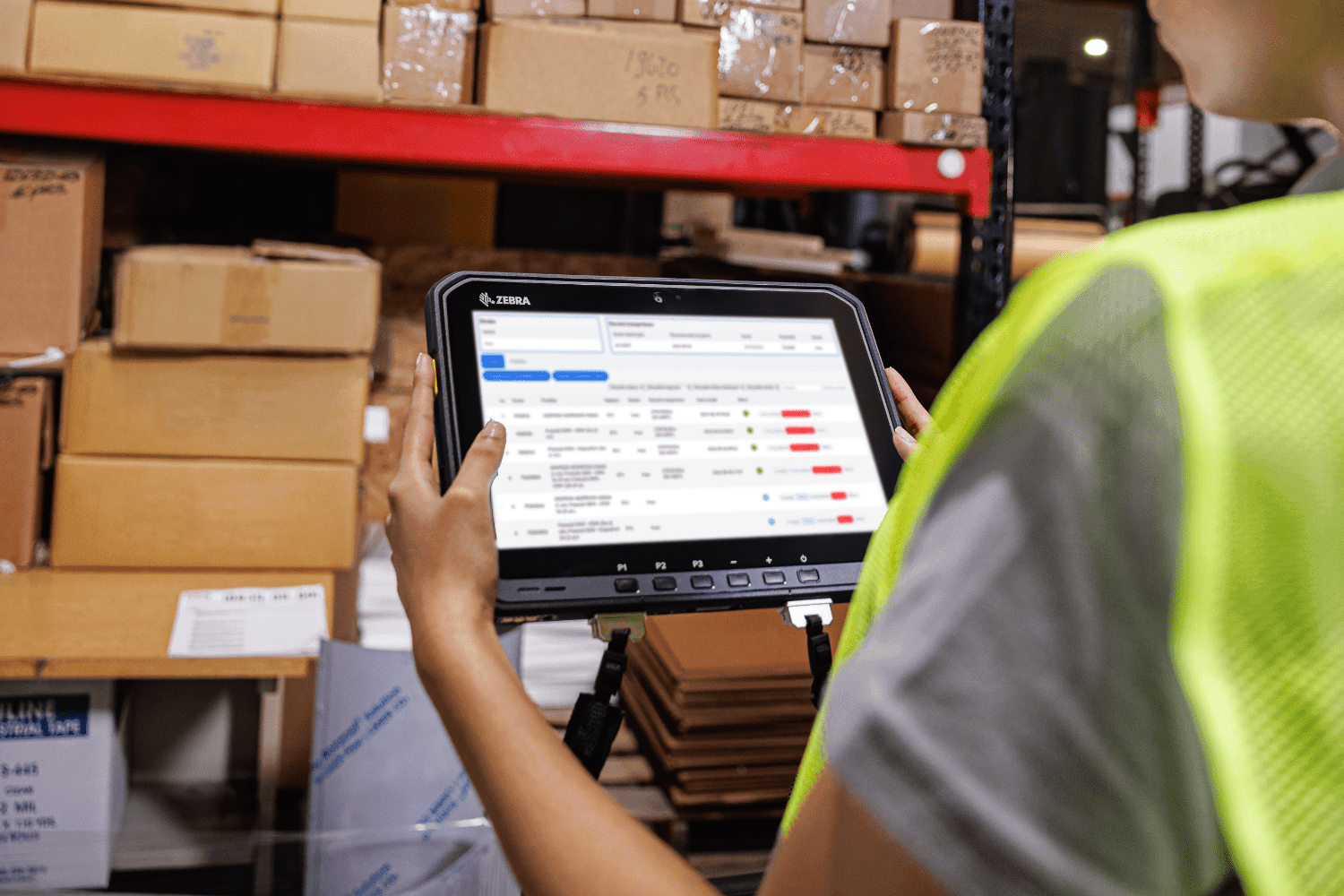

In the project, we utilized advanced solutions from Zebra Technologies, with whom MANUCO collaborates as an implementation partner, reseller, and integrator. We integrated the software with Zebra devices, created a dedicated print driver, and implemented solutions for tracking the flow of goods. Key elements included reliable thermal printers and innovative Zebra ET40 (Wi-Fi) and ET45 (5G) industrial tablets, enabling automated information flow management.

In addition to delivering and configuring Zebra Technologies devices, we conducted comprehensive training for employees on using the new solutions. These training sessions ensured the BWS Expo team was fully prepared to effectively use the implemented tools, contributing to the swift deployment and adaptation of new technologies in daily operations.

Implementation Results

The results of the implementation exceeded the client’s expectations and significantly improved BWS Expo’s logistics operations efficiency. Key benefits include:

- 35% reduction in logistics handling time – significantly accelerated all processes.

- Full control over warehouse management – real-time inventory monitoring capability.

- Complete accountability of goods flow and easy cost reporting – transparency in data analysis.

- Employee workload reduction through process automation – allowing focus on more strategic tasks.

- 15% reduction in the number of required transports – more efficient logistics planning.

- 85% reduction in errors – elimination of mistakes through automation.

- Better utilization of available resources – optimized warehouse operations.

- Achieving “just-in-time” deliveries – reduced logistics costs related to storing goods at trade fair locations.

Summary

The implementation of a comprehensive logistics process automation system for BWS Expo demonstrates how modern technologies can revolutionize a company’s operations. Thanks to the collaboration with MANUCO, BWS Expo not only optimized its processes but also significantly reduced costs and improved work efficiency.

If your company is also facing challenges in logistics and warehouse management, contact us. At MANUCO, we will help you plan and implement solutions that will revolutionize your business processes and deliver real savings.

Schedule a free consultation